Andrew Holsaeter

R&D Engineer specializing in offshore drilling automation

Drillbotics

2017

Size: 7

Budget: $200,000

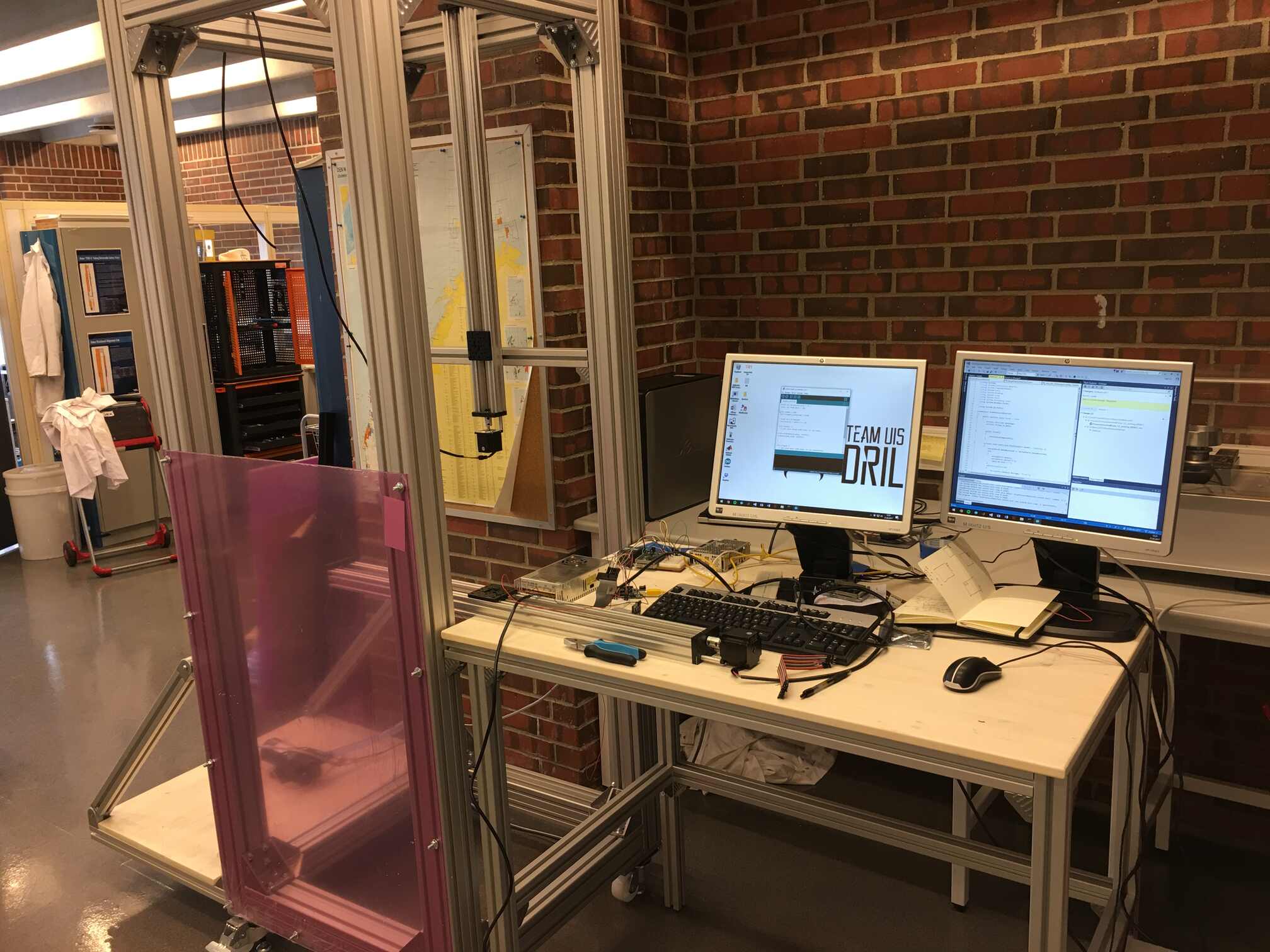

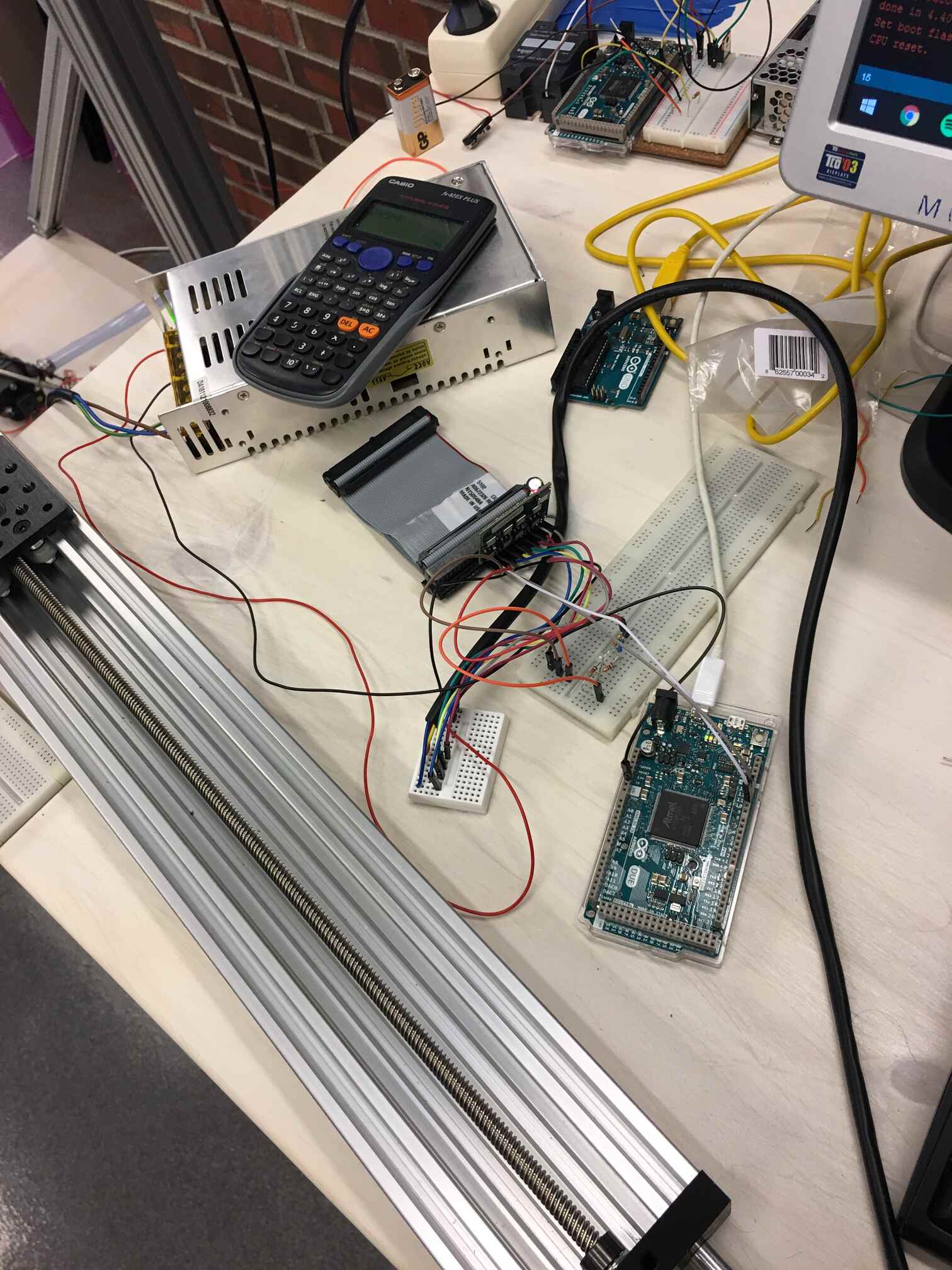

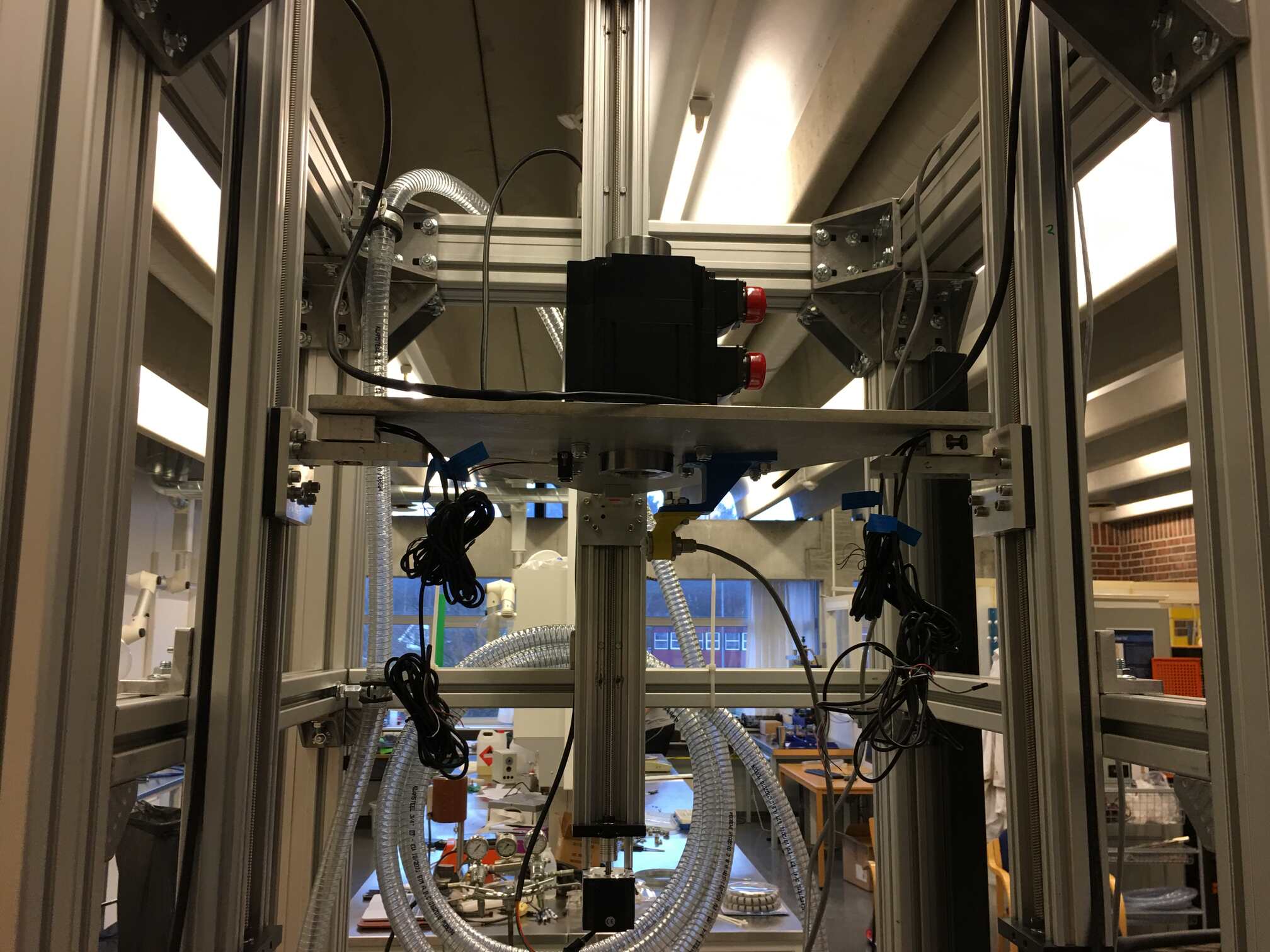

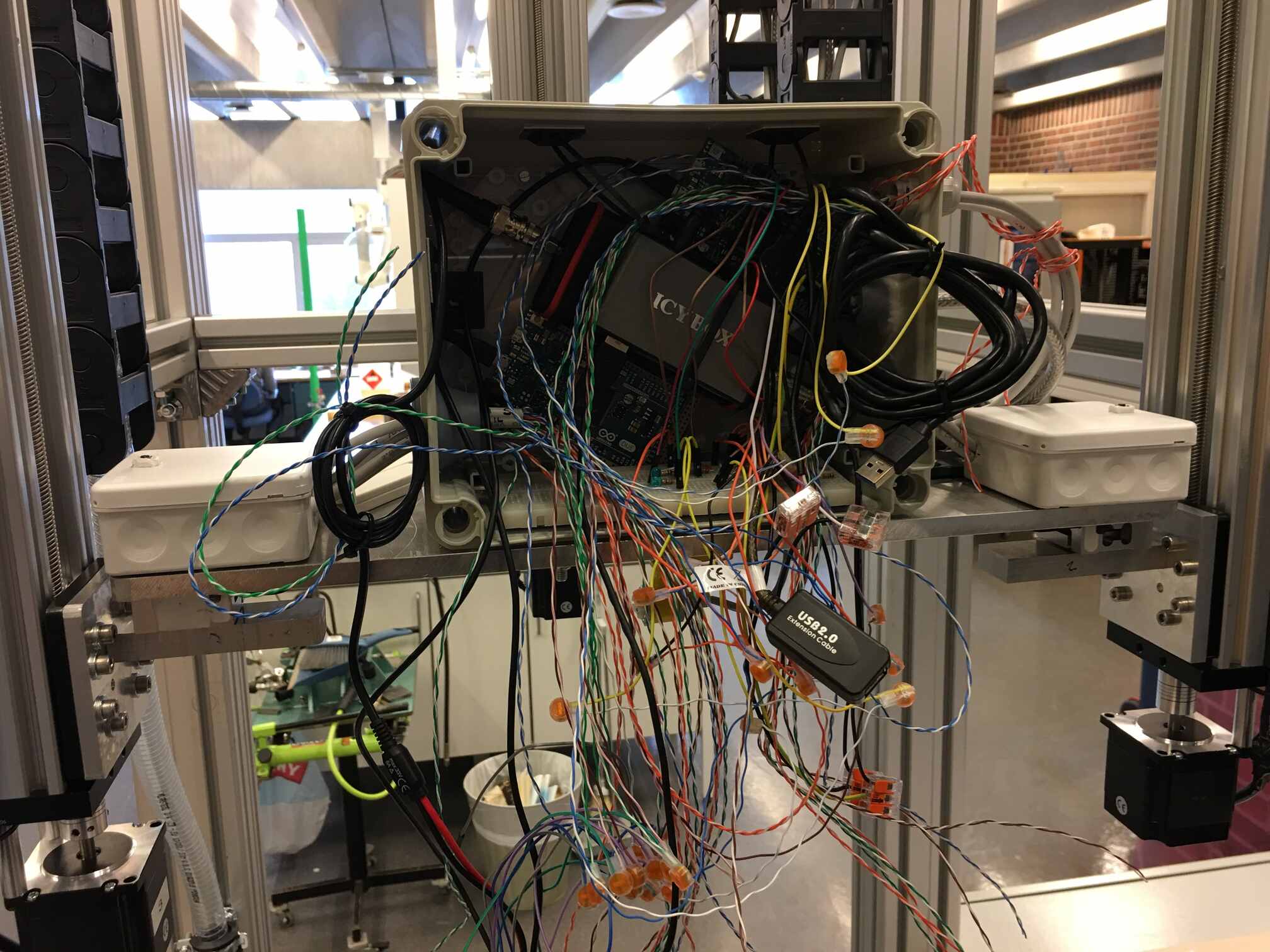

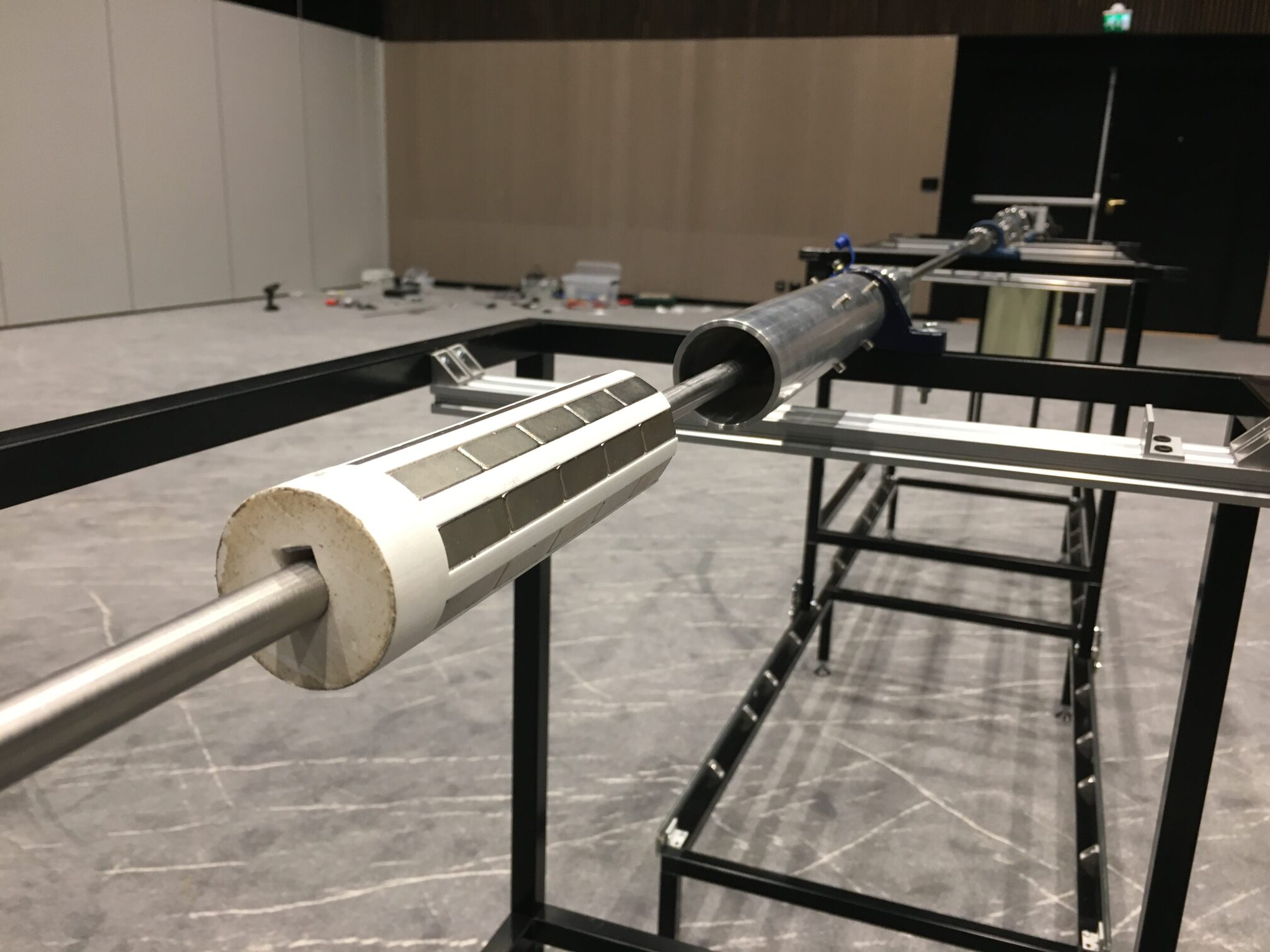

A university competition to build a completely autonomous lab-scale drilling rig.

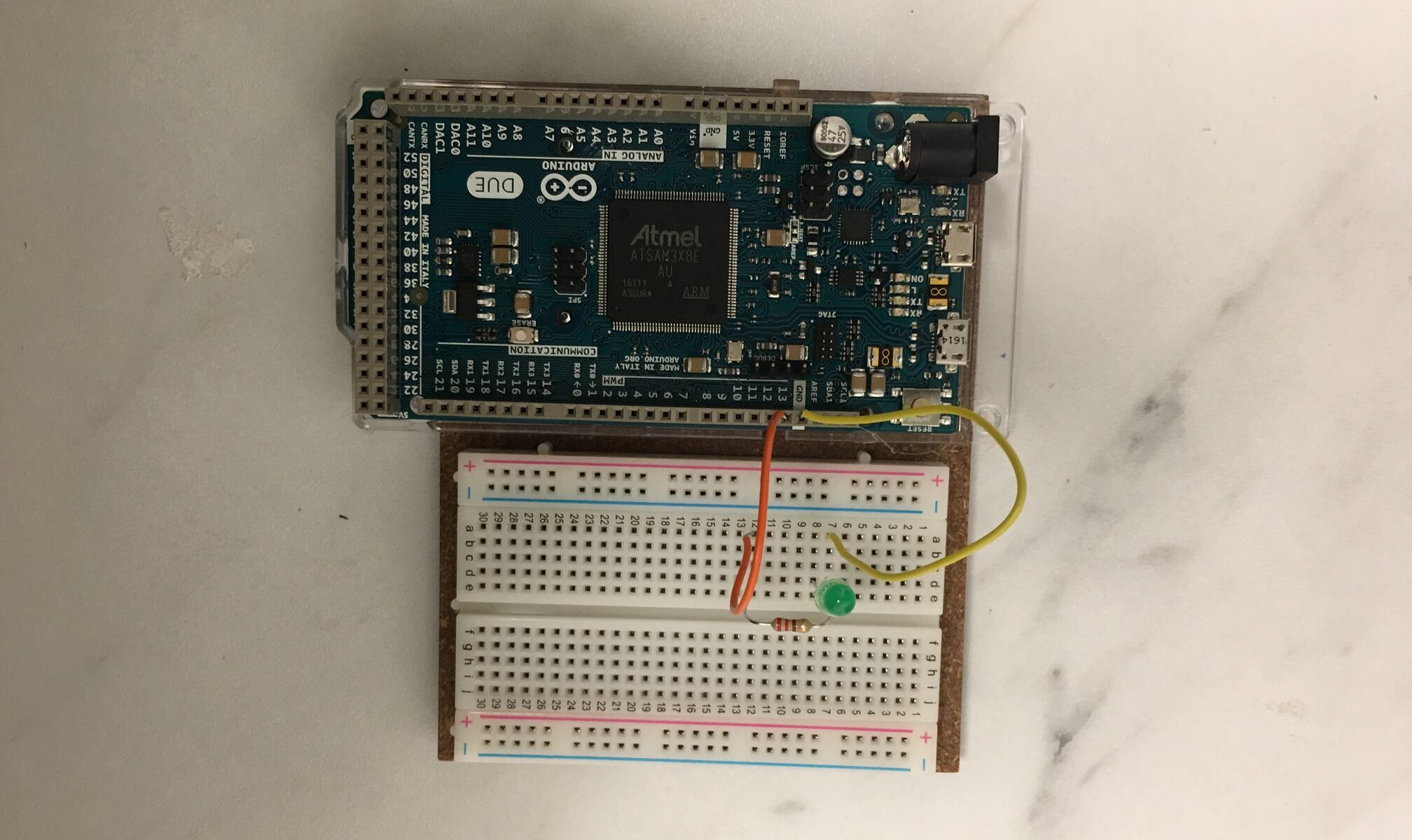

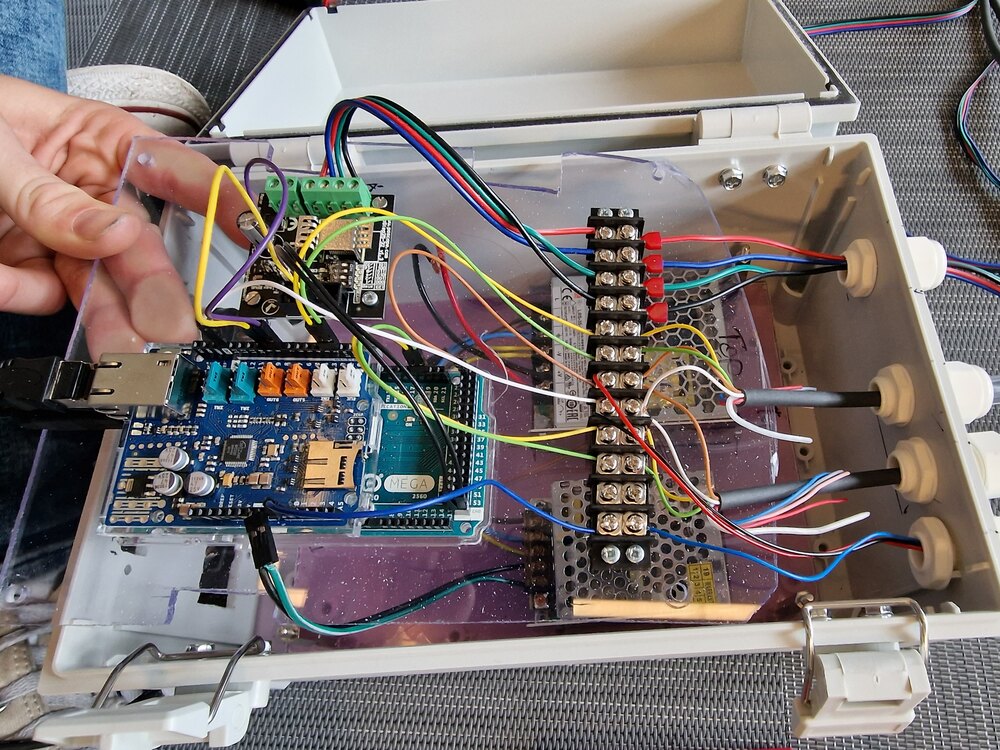

UiS Drillbotics This was the project that sparked my love for electronics, programming, and robotics. In my last semester of my masters degree in Petroleum Engineering, I blindly signed up to be the last member of my universities Drillbotics team and was handed the role of software/hardware programmer which to my surprise, no one else wanted. What followed was a semester full of all-nighters, hair pulling, and constant confusion but I loved every second. In the end, an unfortunate last minute switch to a different stabilizer resulted in failed pipe fittings and we finished tied for 3rd.

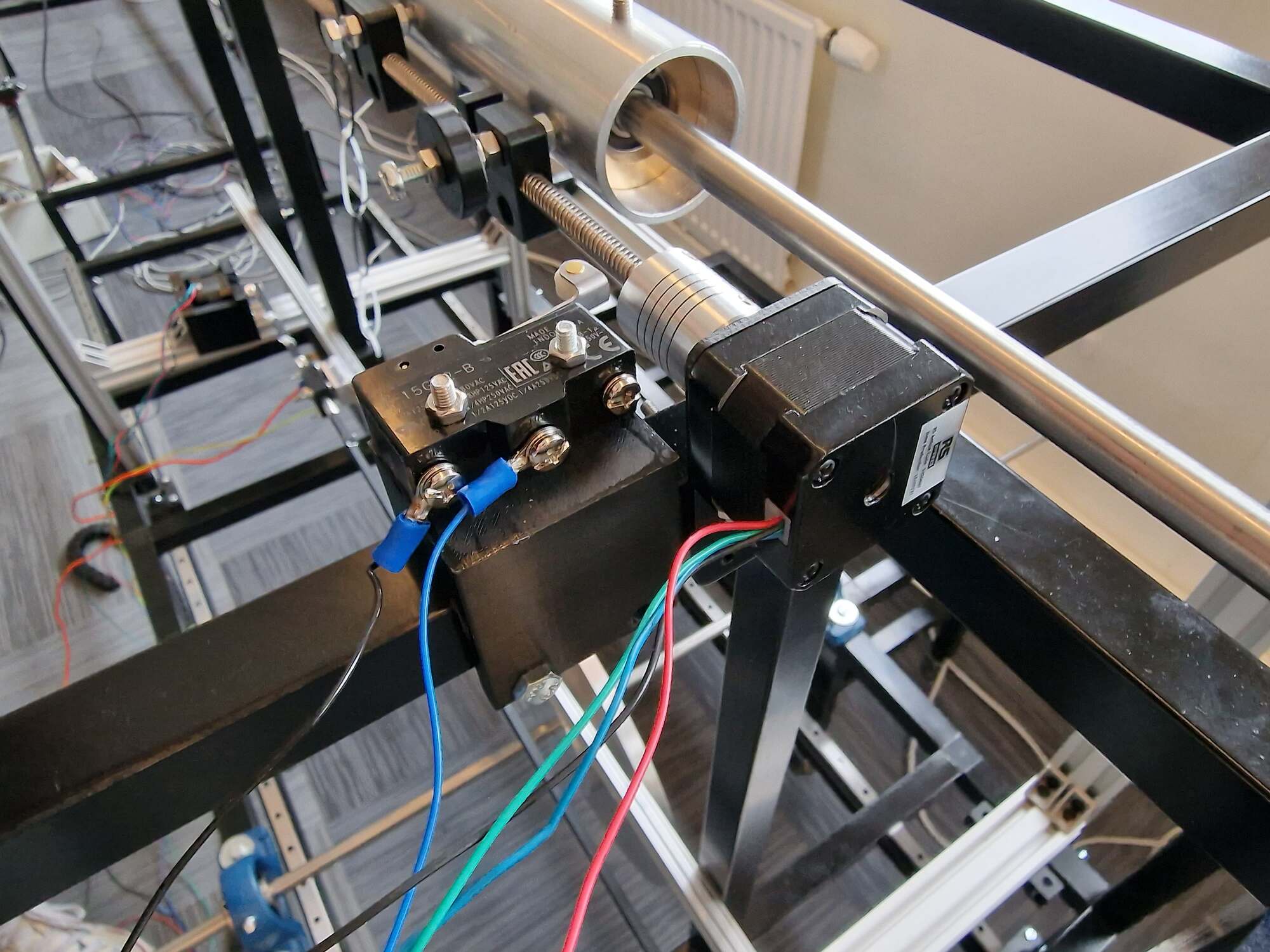

Distributed Drilling Control

2021-2022

Size: 5

Budget: $~250,000

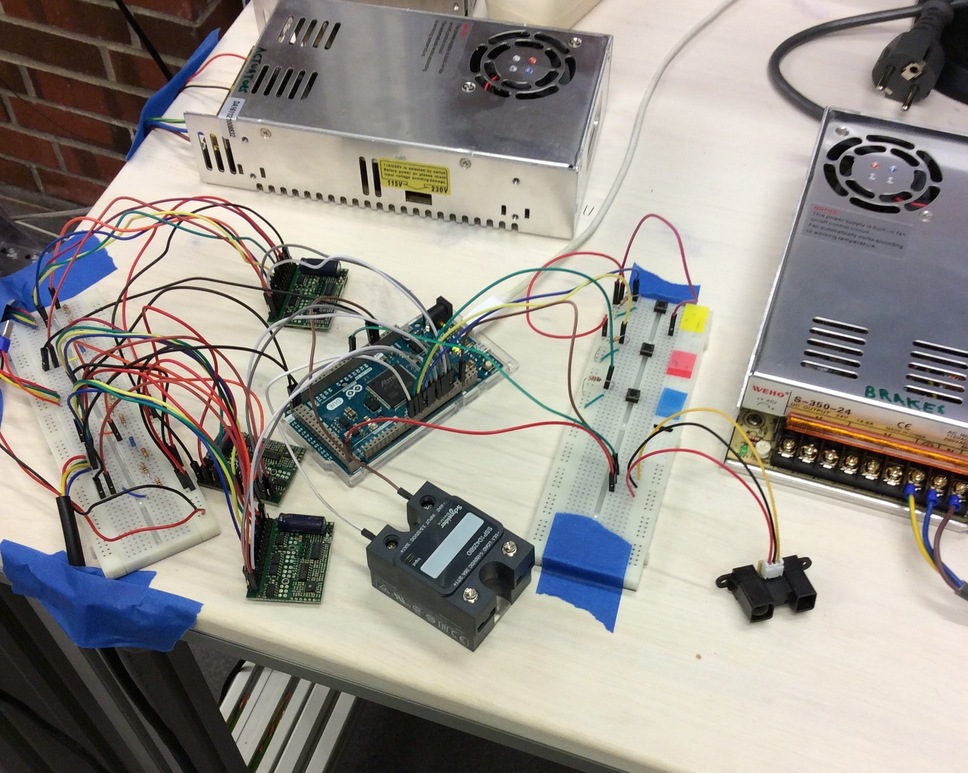

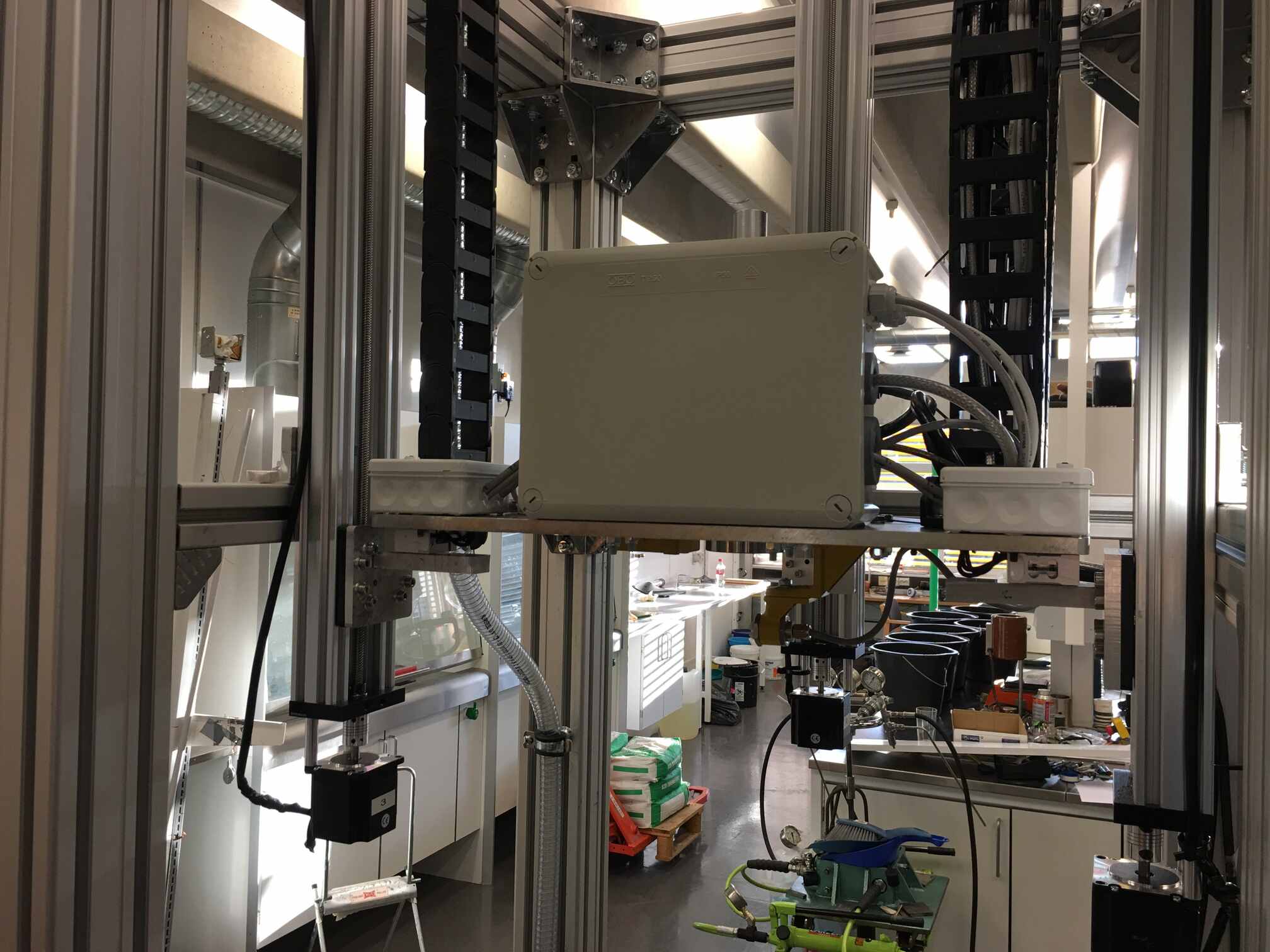

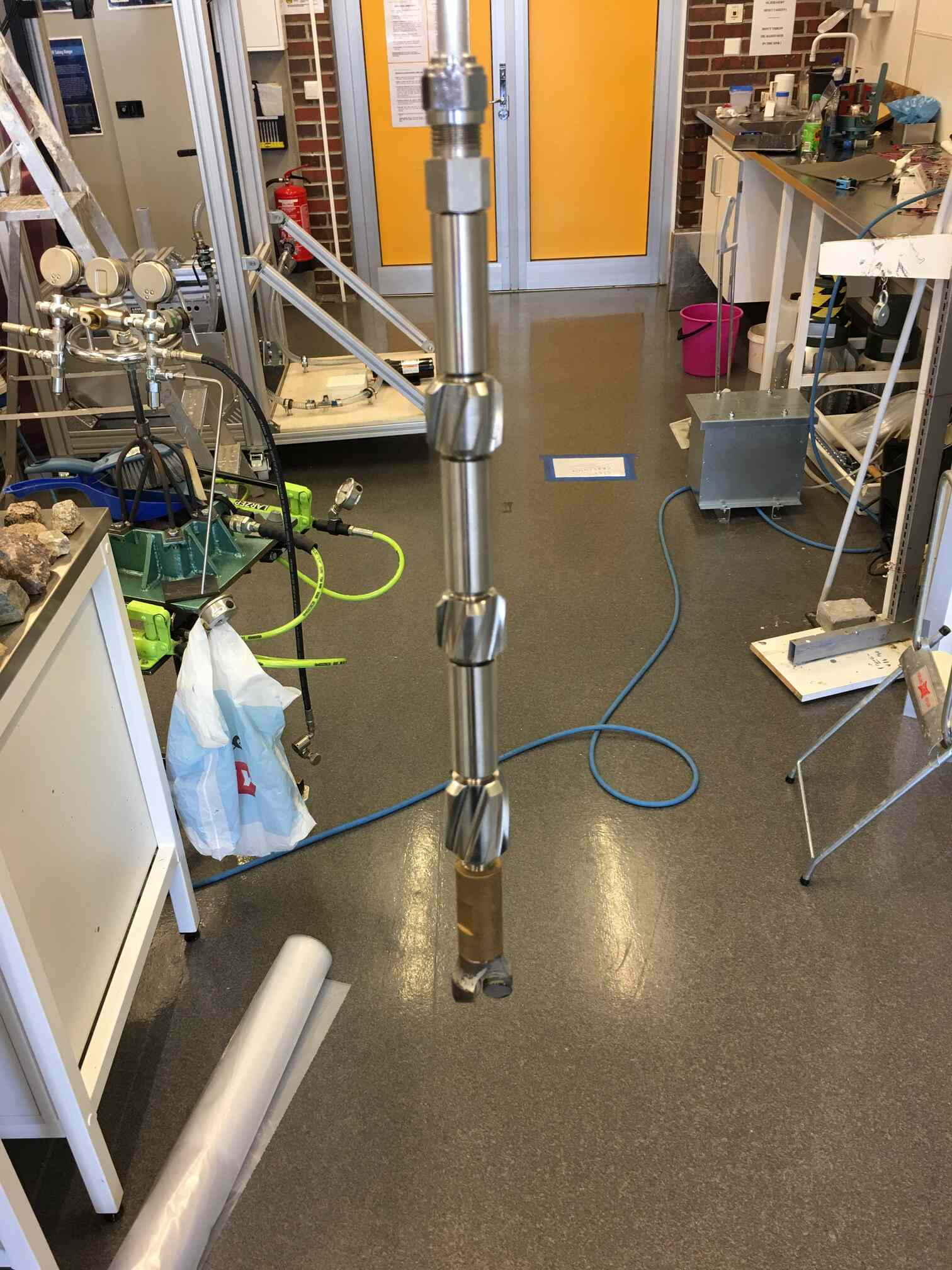

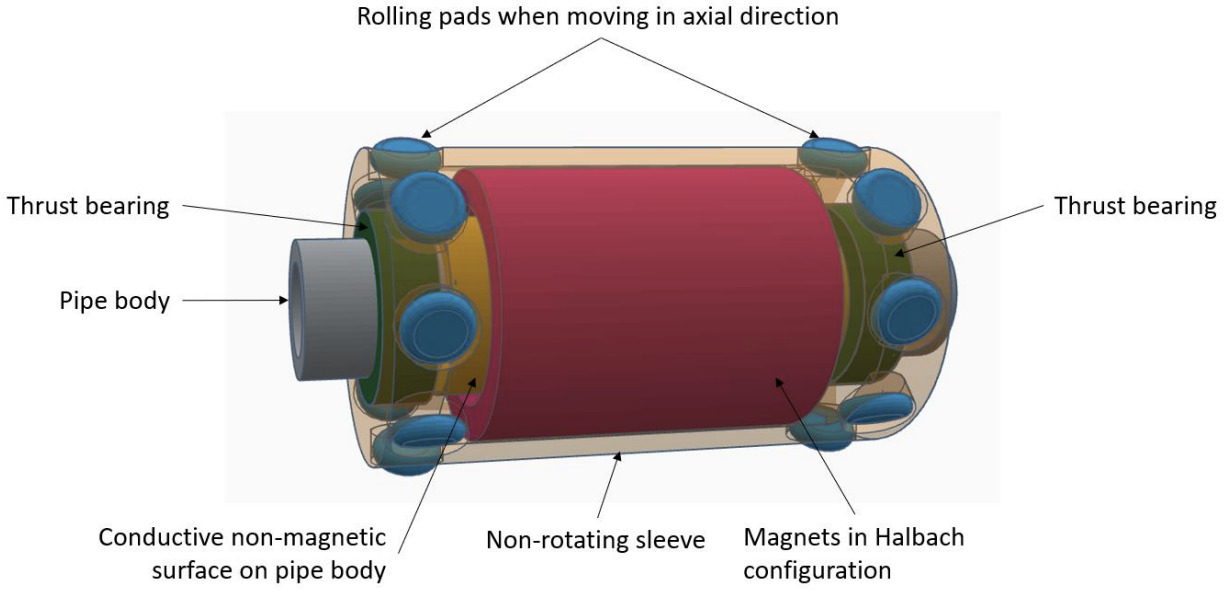

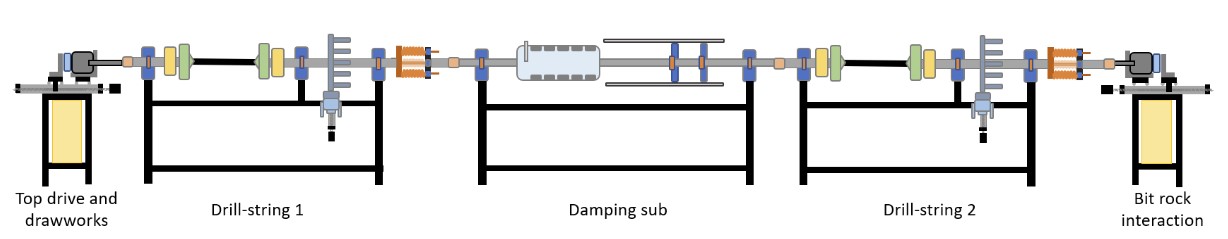

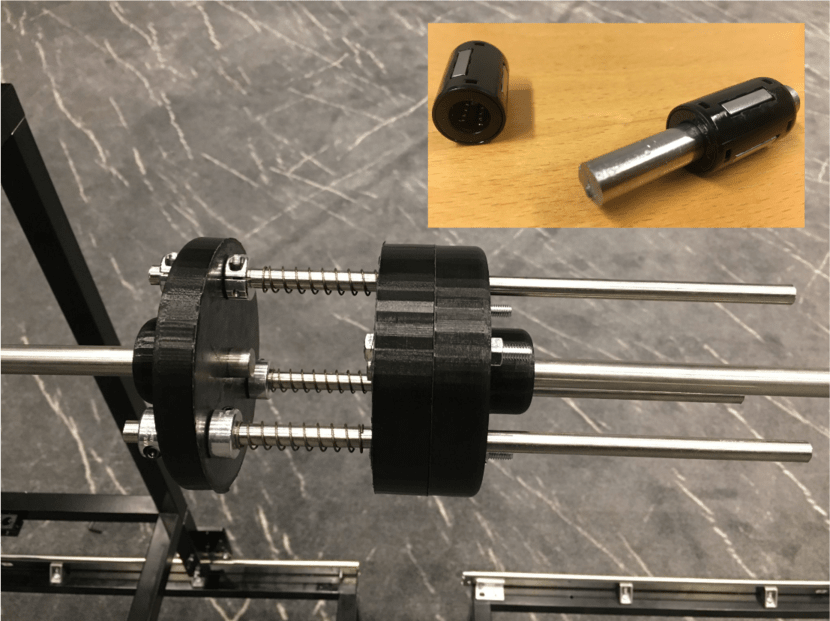

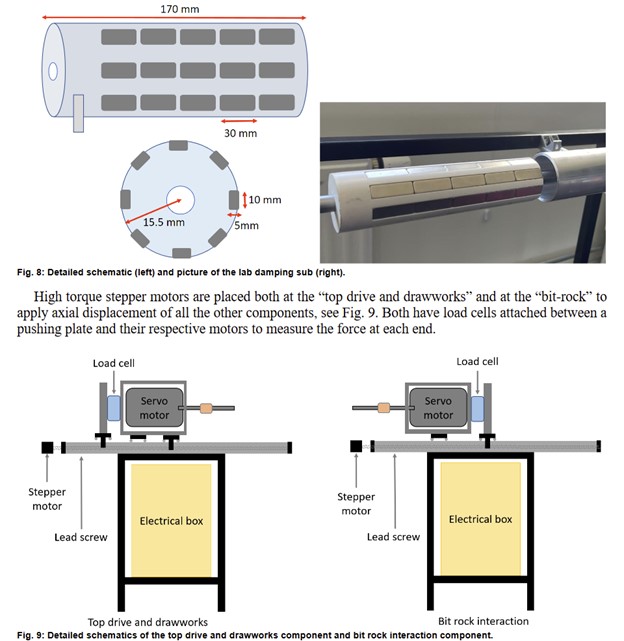

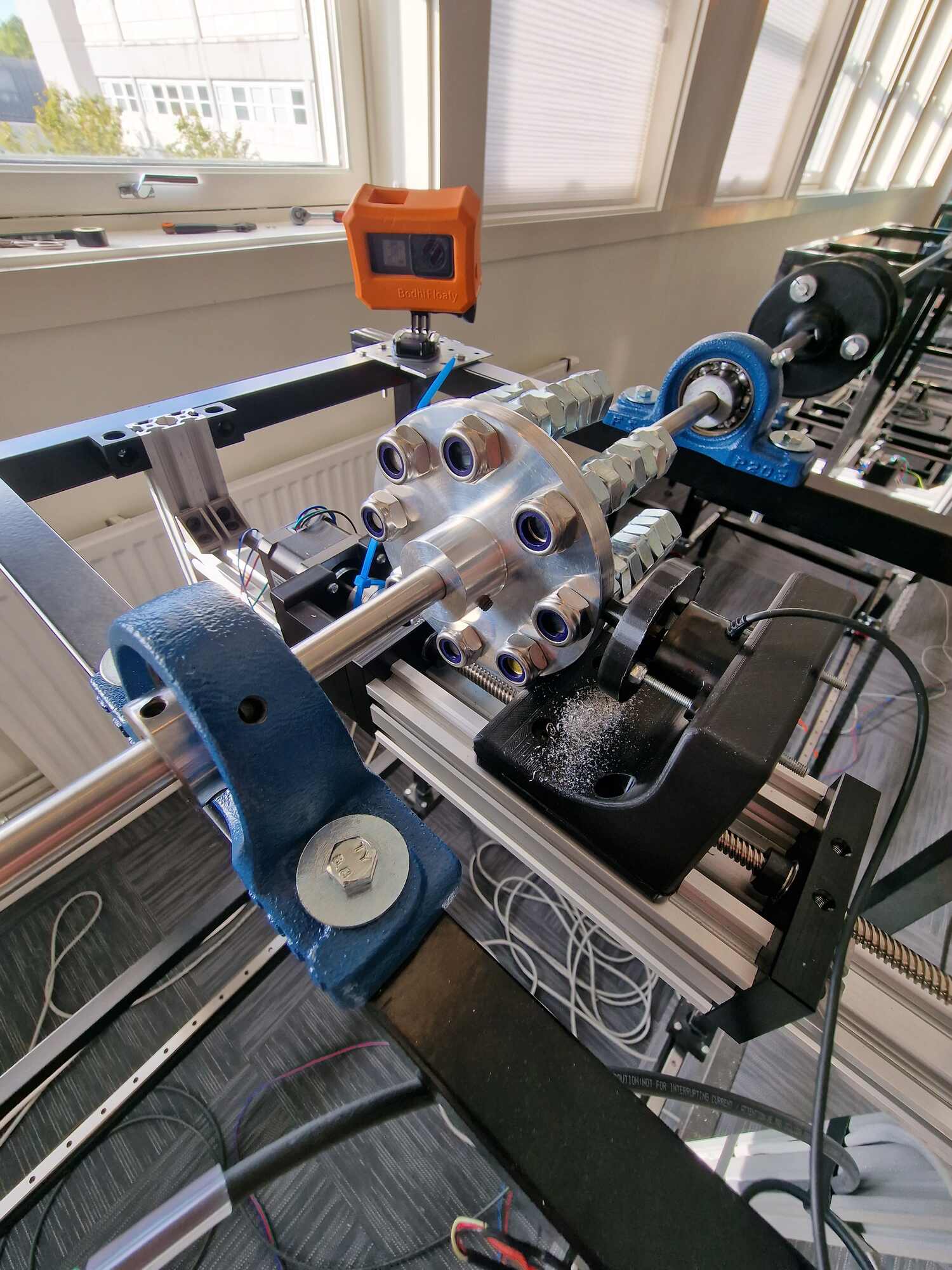

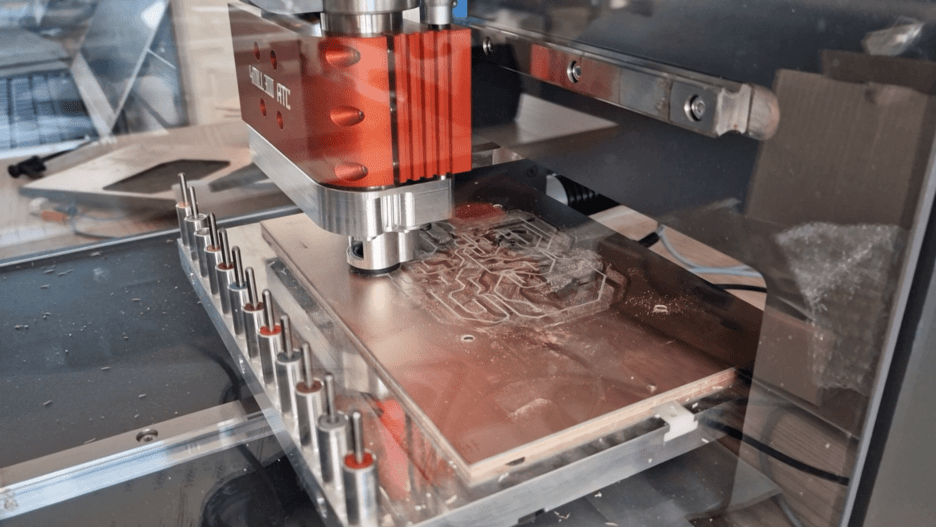

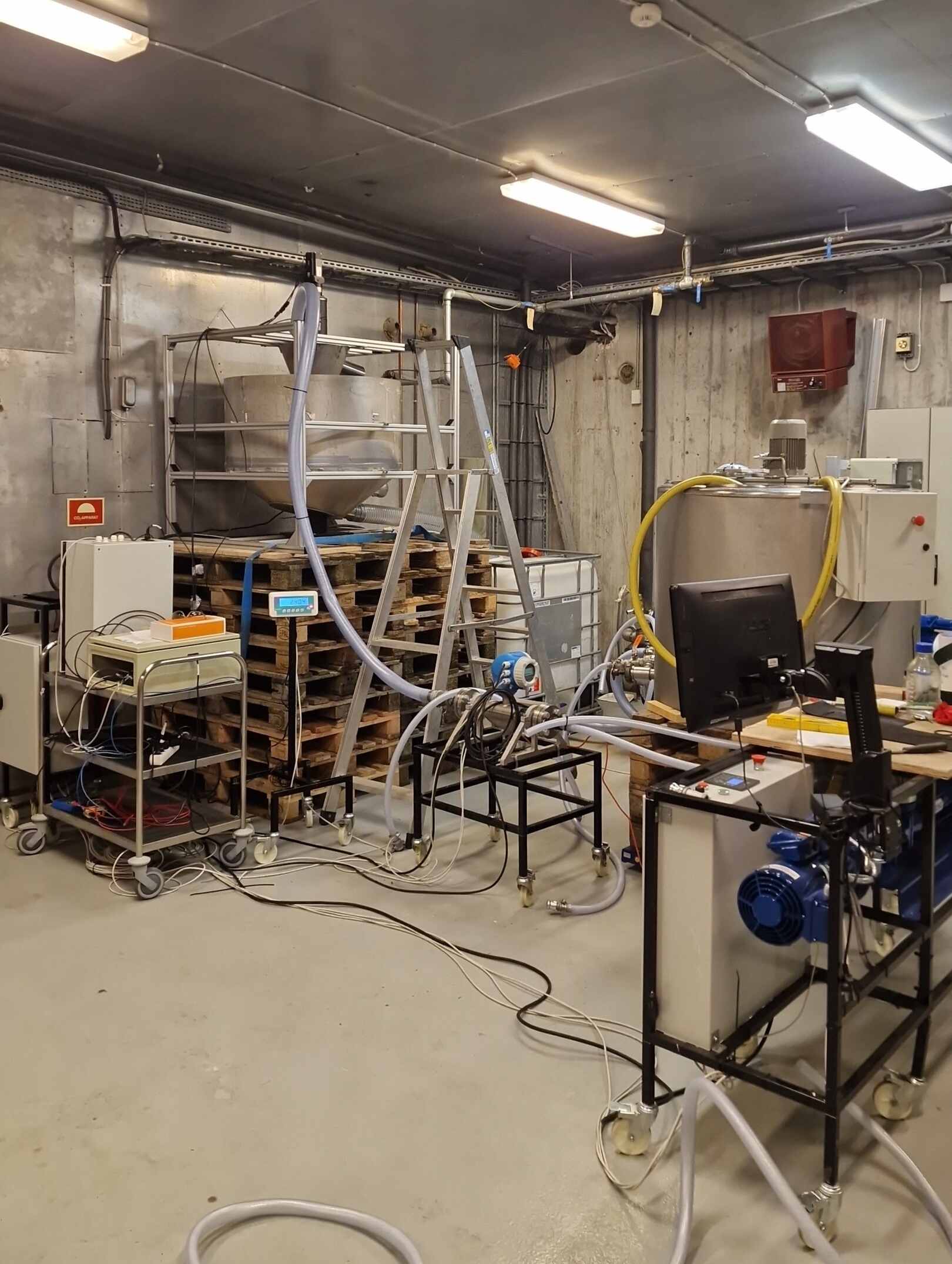

This project aimed to test and validate a completely new and innovative way of mitigating drillstring vibrations. But in order to test that, a physical drilling simulator needed to be built around it.

Main Development Engineer Design, construction, and full-stack programming.

Flow Rate Out Sensor: Proof of Concept

2018

Size: 2

Budget: $~50,000

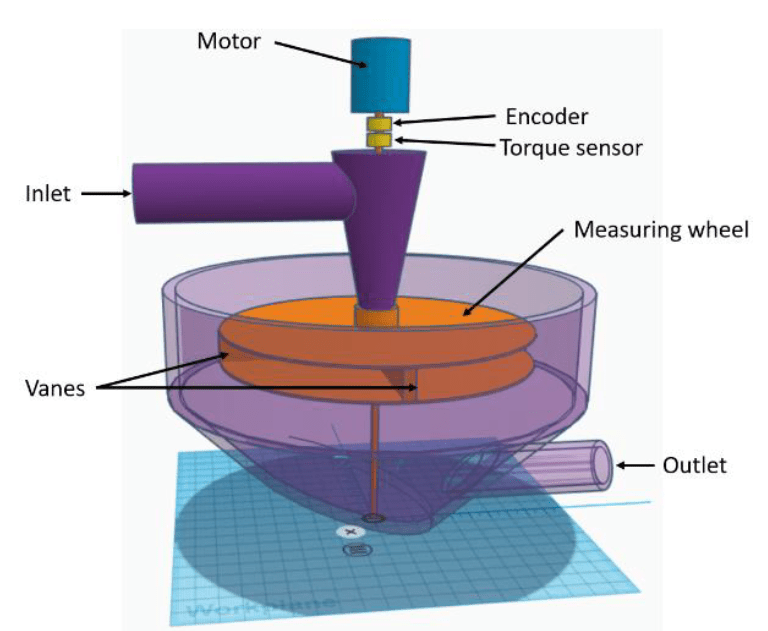

"The Macondo blowout in 2010 was caused by a series of events, and a main critical factor was the lack of accurate flow measurement as pointed out in the investigation that followed. The commonly used measurement device, the flow paddle, used on Deepwater Horizon, has an accuracy of 10%. This technology is still preferred due to the lack of alternatives."

Thus, this project aimed to test a new and innovative design to replace the flow paddle which could have helped preventing the disaster of 2010.

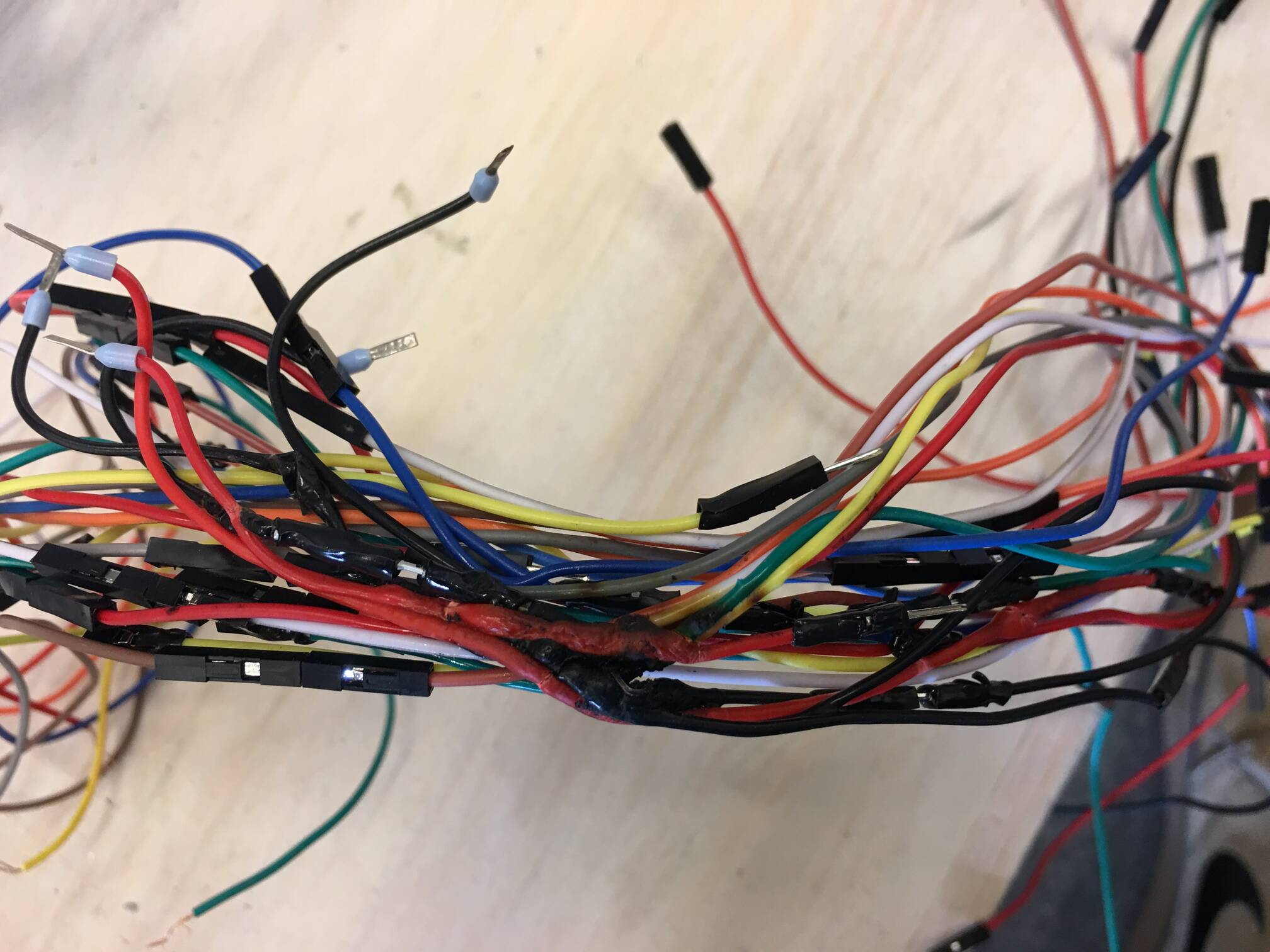

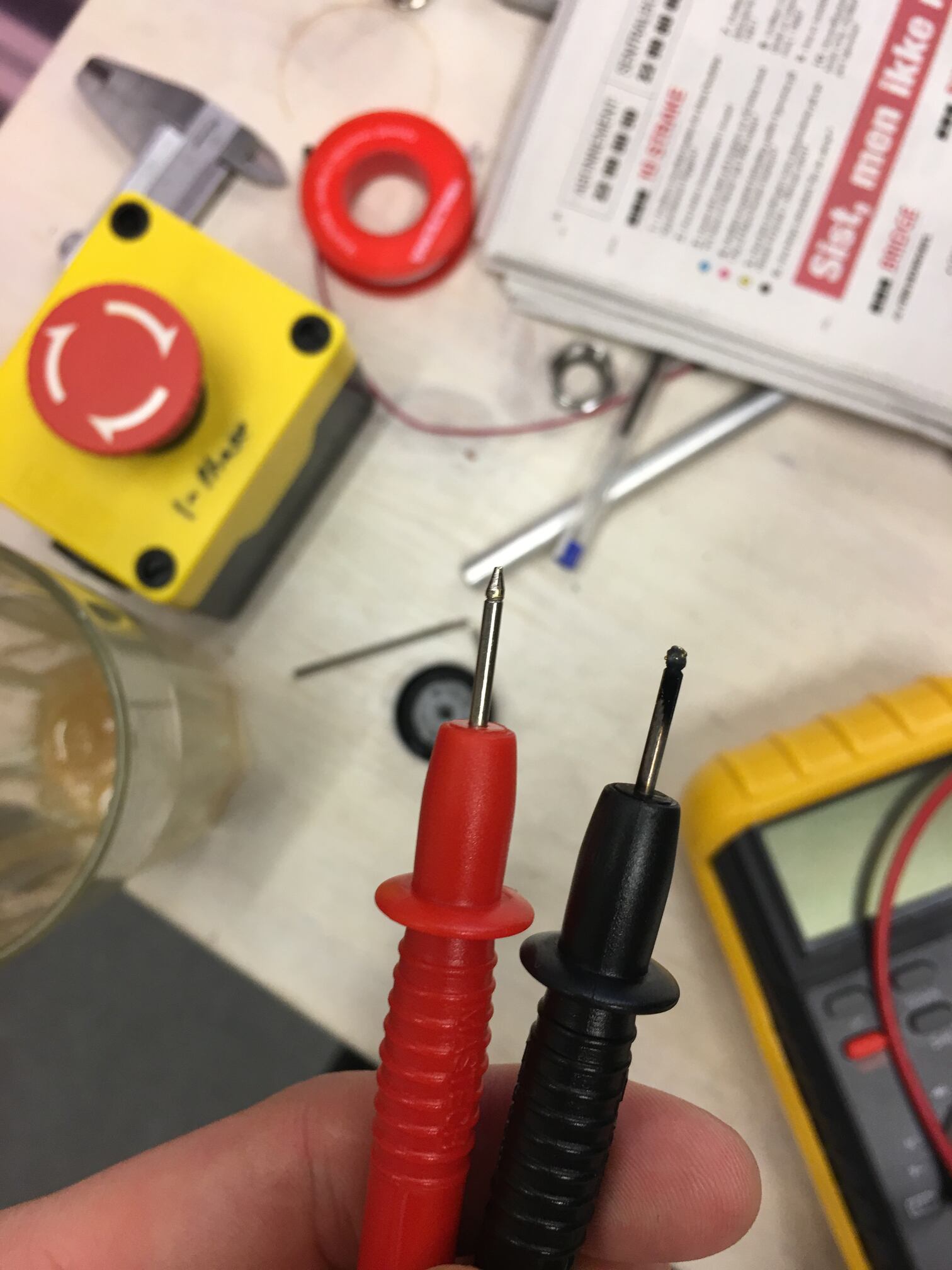

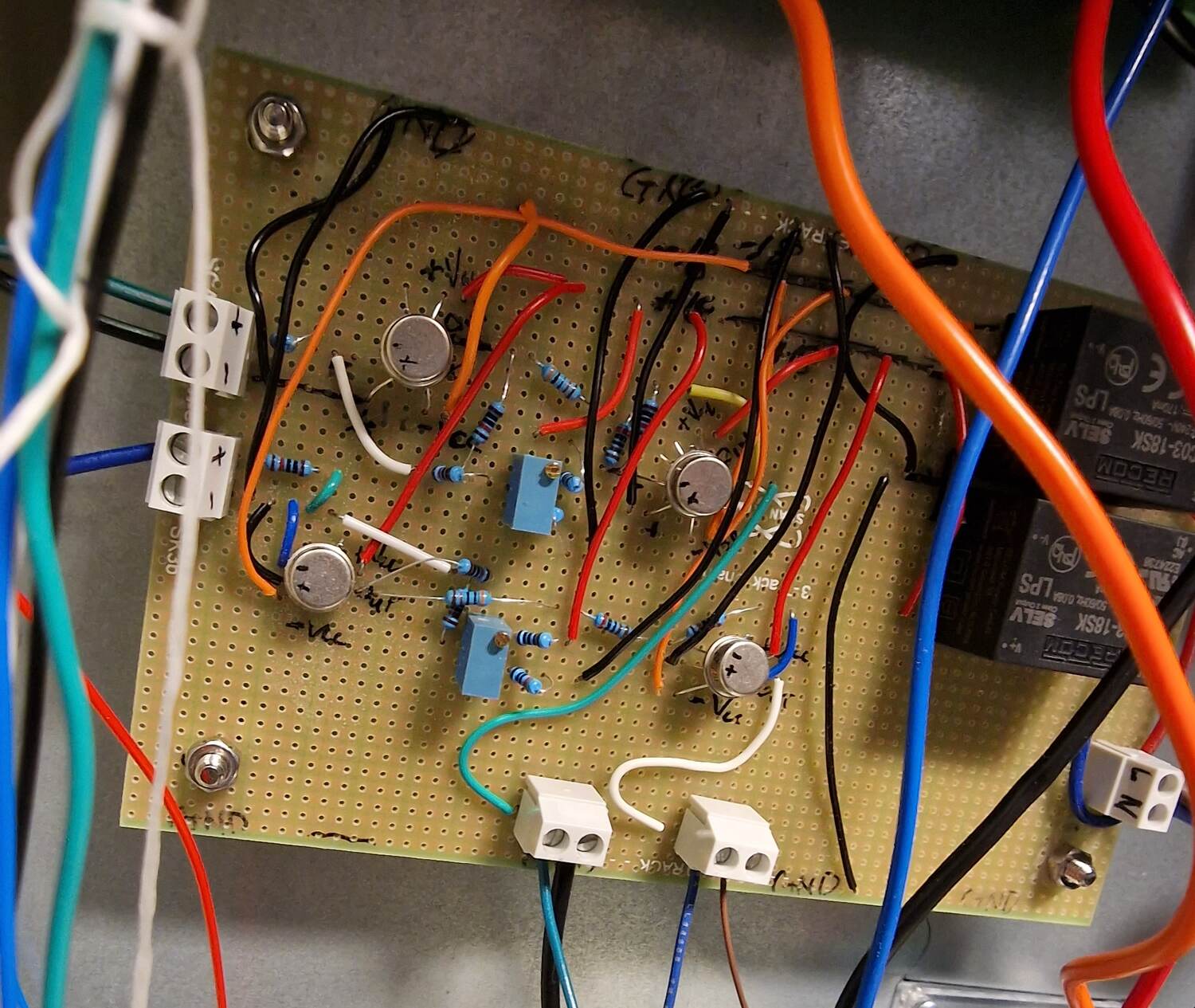

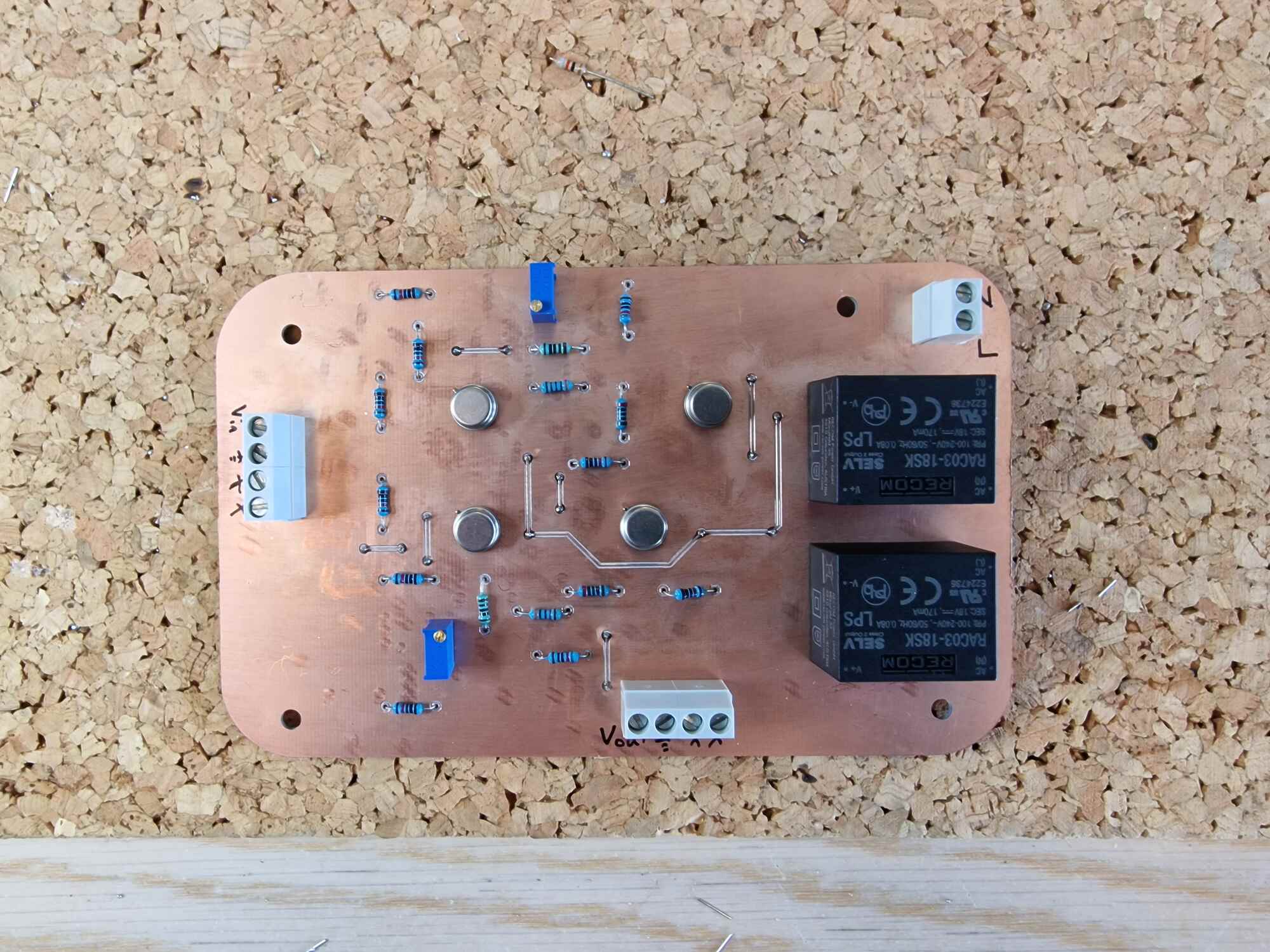

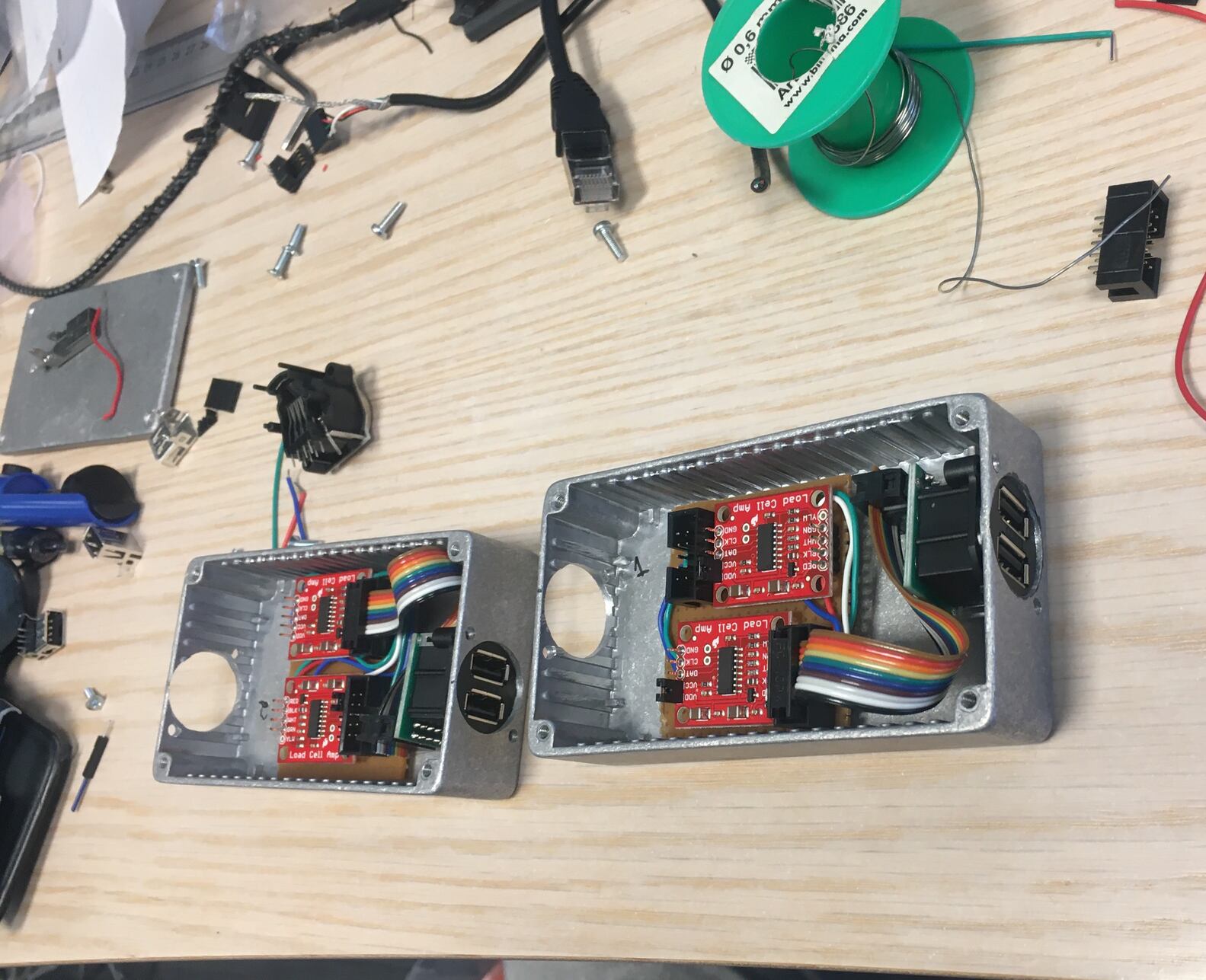

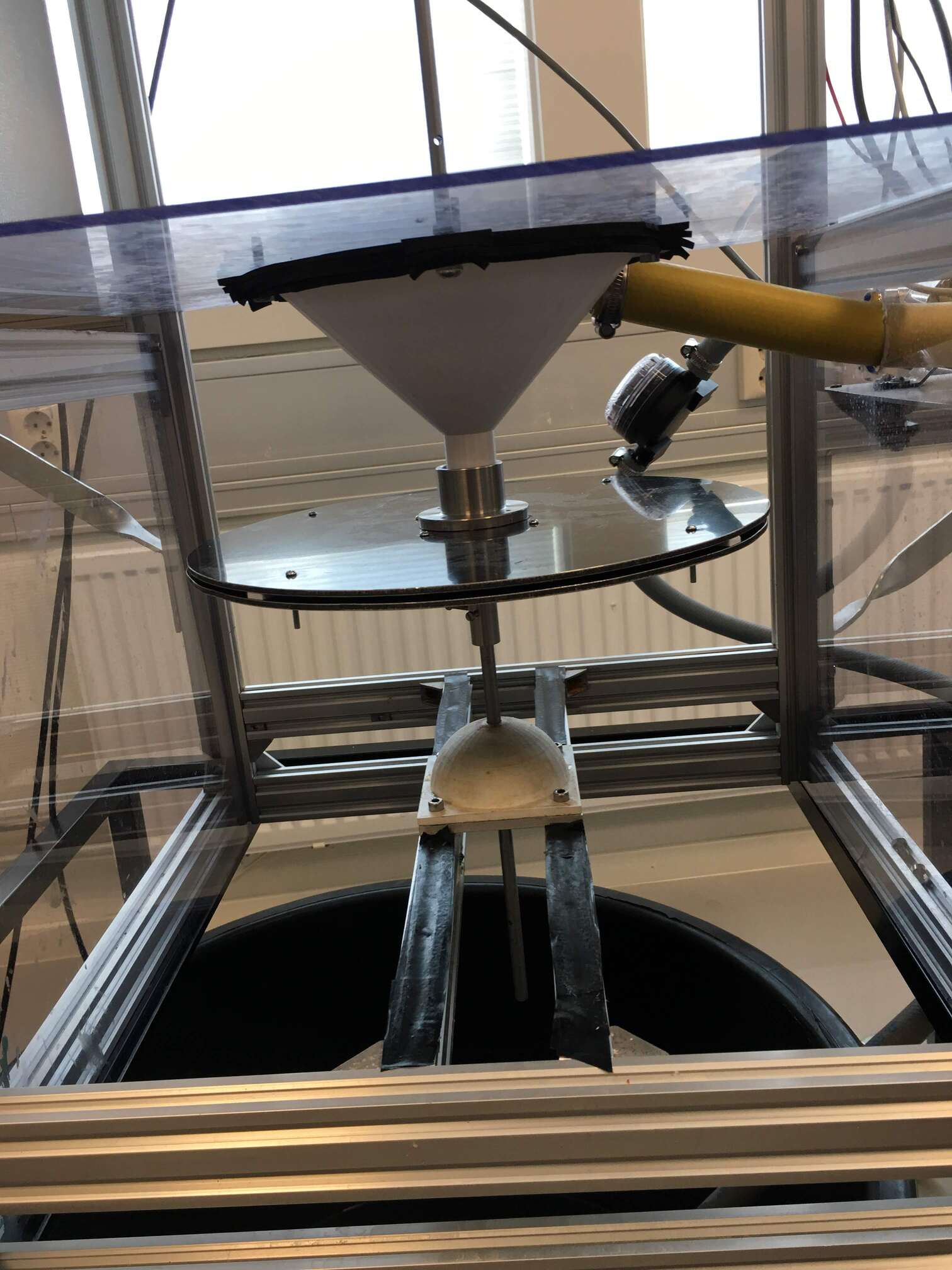

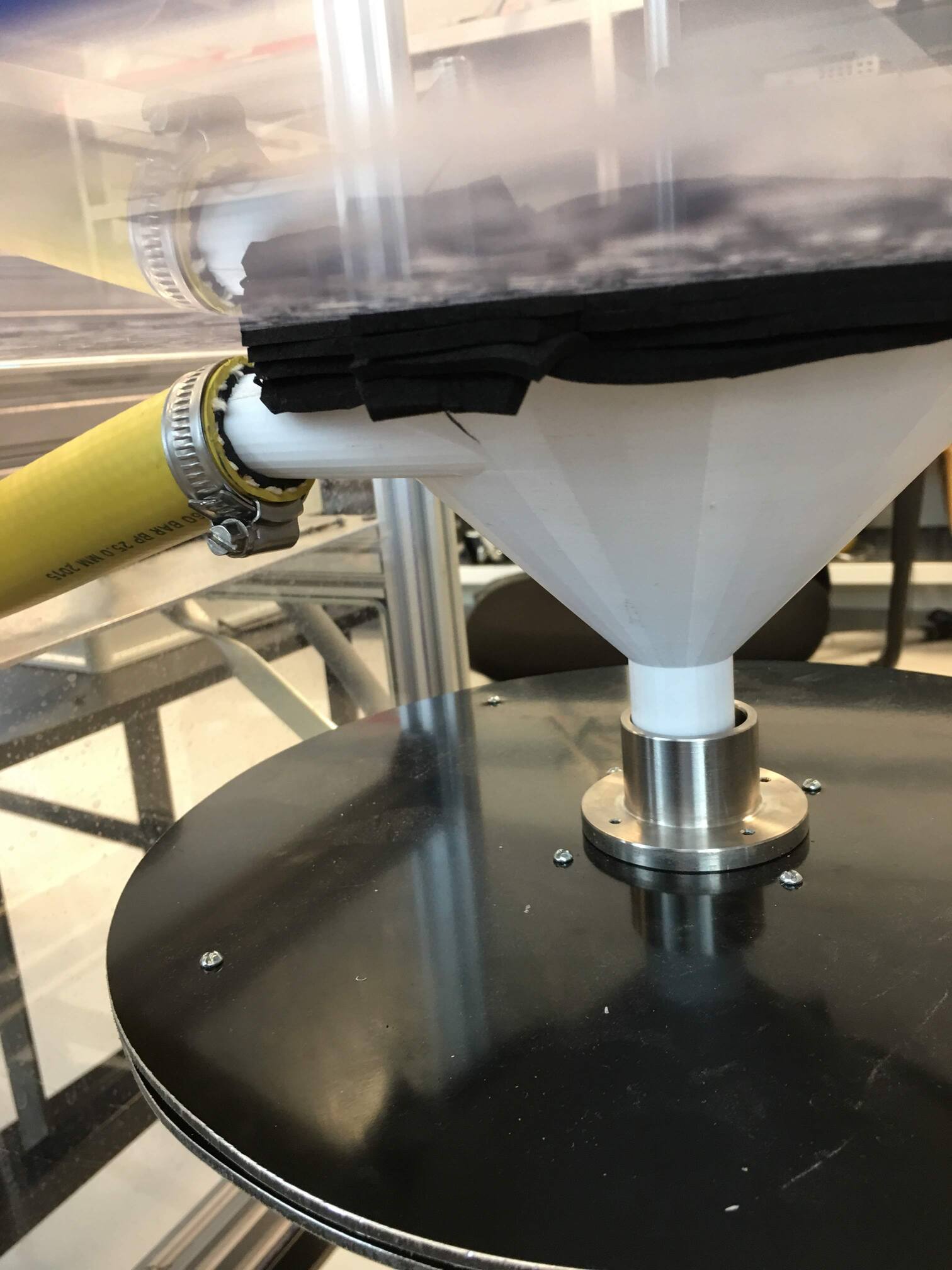

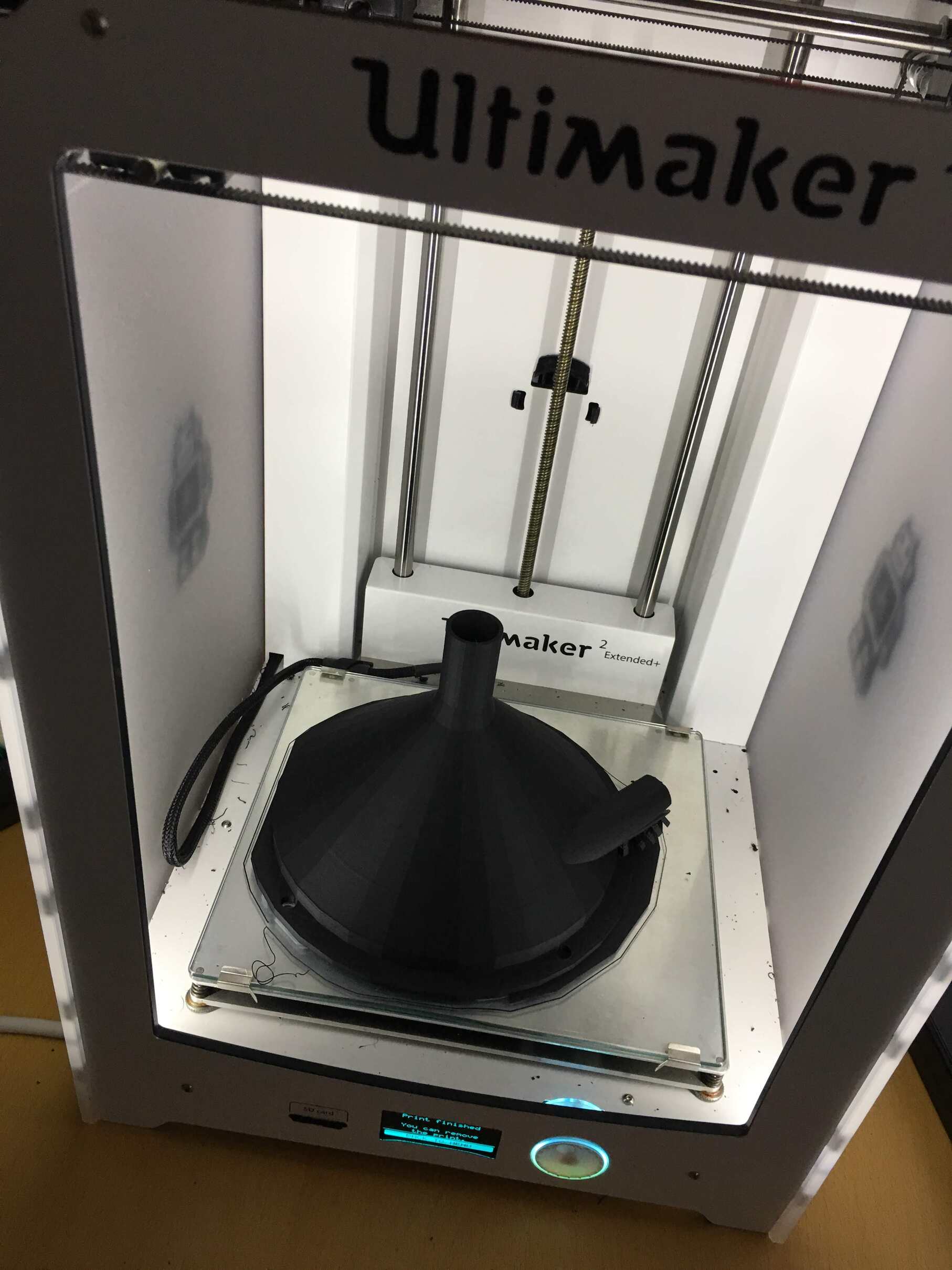

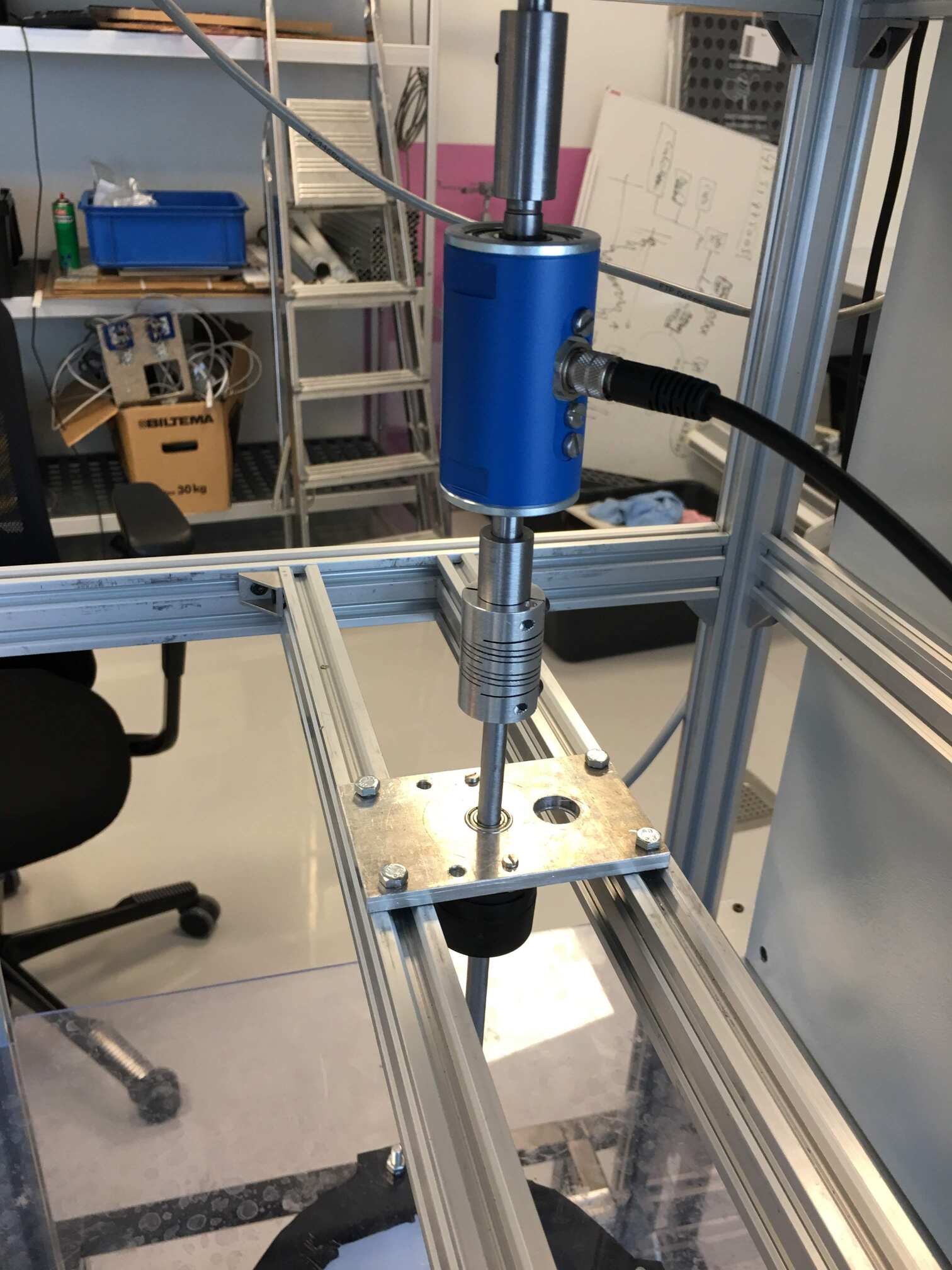

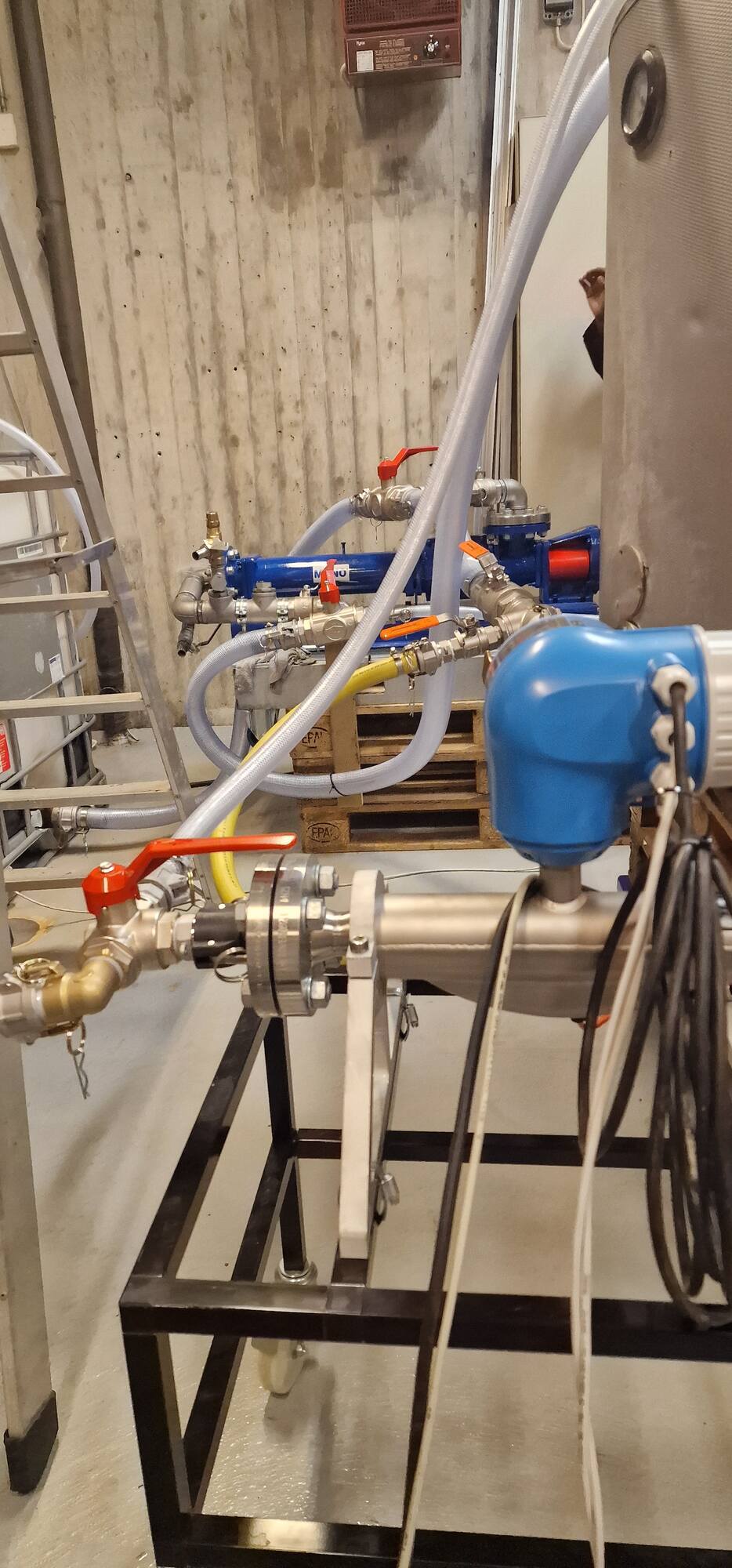

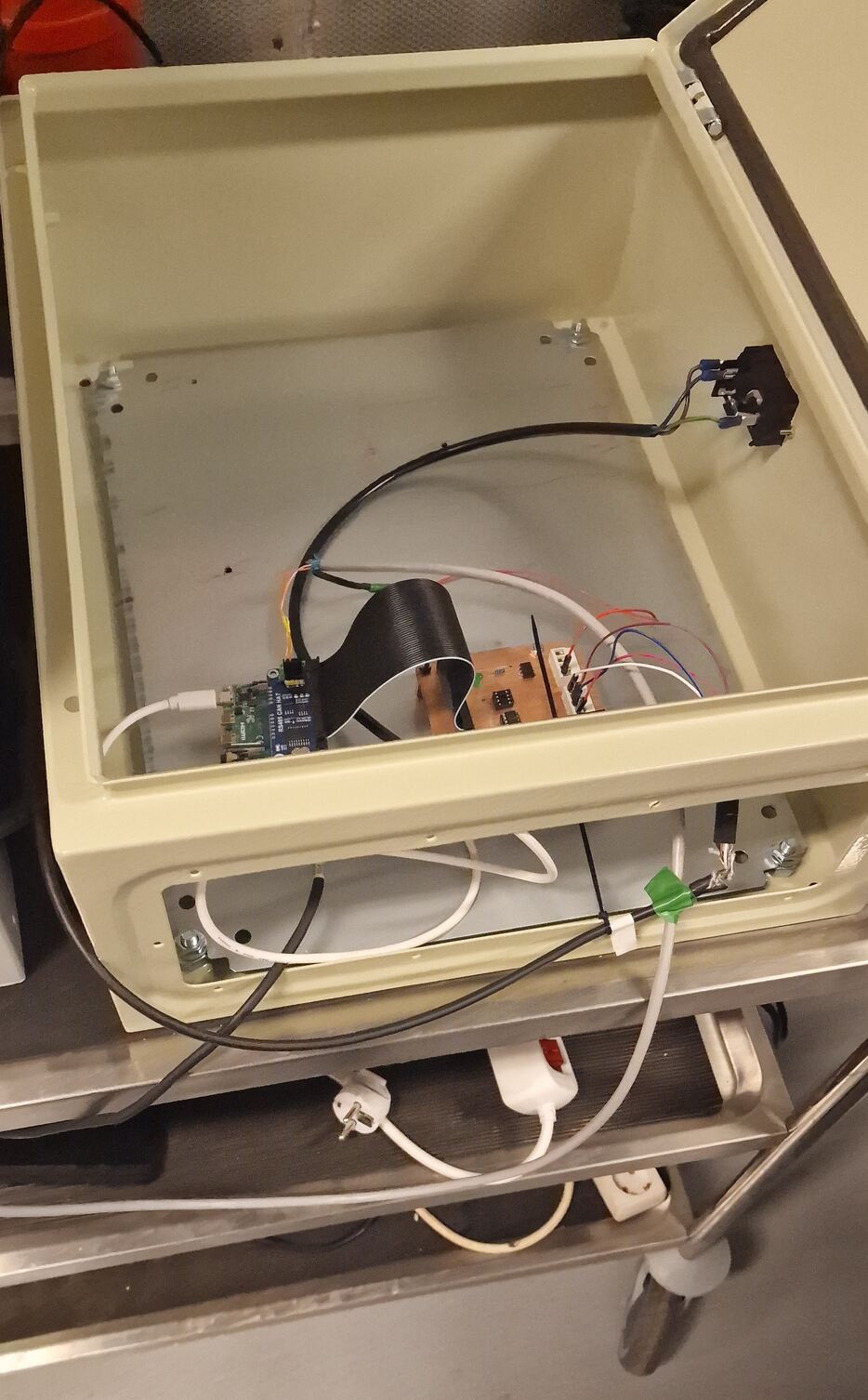

Flow Rate Out Sensor: (POC) I came into this project after an initial build from our chief scientist. He found the torque measurement wasn't sufficient enough as well as a problem with the collecting funnel which needed to be addressed. I installed a new high precision torque sensor along with a 12-bit ADC, cleaned up/simplified some of the electrical work and made progressive improvements to the collecting funnel and circulation system. The successful results of this project led to a follow up verification project being awarded as well as a patent.

Flow Rate Out Sensor: Verification

2023-2024

Size: 5

Budget: $500,000

Following the success of the POC project, a new project was awarded to NORCE to develop a small~medium scale sensor that would go up to 200 l/min and test more fluids including actual drilling mud provided by industry partners.

Flow Rate Out Sensor: (Verification) This project was of particular enjoyment as I really got to combine all my fields of knowledge that I had been developing the past years. Docker, Python, electronics, databases, and machine learning modelling were all the things I got to use on this project.

DigiWells

2020-2028

Size: 30+

Budget: $9M

A long term center to develop new knowledge, methodologies, and innovative solutions to improve the well delivery process enabled by digitalization, new sensors, high speed telemetry, automation, and autonomy.

Microservices Our aim at NORCE with this center is to develop drilling automation based around microservices. I was responsible for building the entire microservice architecture from the ground up including installing the on-premis servers, creating the development environments, and complete setup of a Kubernetes production level cluster.

Publications

- Experimental Verification of Vibration Mitigation Through a Viscous Damping System Along the Drill String

- Development and Validation of a Rotating Wheel Coriolis Mass Flowmeter for Accurate Measurement of Drilling Fluid with No Pressure Loss

- Integration of Modeling and Drilling Incident Management of a Real-time Lab-scale Autonomous Drilling Rig